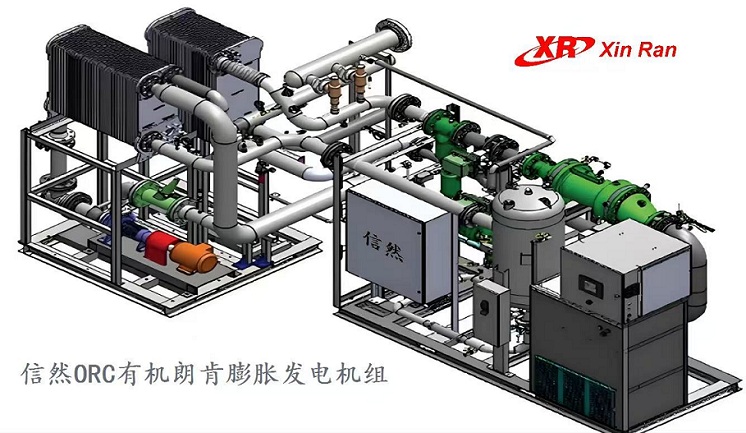

Working principle: Organic working fluid (such as R245fa) is used as the medium to achieve the conversion of thermal energy into mechanical energy through evaporation, expansion, and condensation cycles. Hot fluids (waste steam, flue gas, etc.) enter the evaporator to heat the working fluid, generating high-pressure steam that drives the screw expander to do work. Finally, the heat is released through the condenser to complete the cycle.

工作原理:采用有机工质 (如R245fa )作为媒介,通过蒸发、膨胀、冷凝循环实现热能到机械能的转换。热流体(废蒸汽、烟气等)进入蒸发器 加热工质,产生高压蒸汽推动螺杆膨胀机做功,最终通过冷凝器 释放热量完成循环。

Application Scenario: It is suitable for low-grade waste heat recovery in industries such as petrochemical, chemical, and metallurgical, as well as for the utilization of solar and geothermal energy.

Efficiency performance: power generation efficiency of 8%-12%, isentropic efficiency of 85%-88%,

The investment payback period can be shortened to less than 3 years.

Modular design: supports 300kW to 20MW

Customized modules to accommodate application needs of different scales.

适用场景:适用于 石化 、化工 、冶金 等行业的低品位余热回收 ,以及太阳能 、地热能 利用。 效率表现: 发电效率 8%-12%,等熵效率 达85%-88%,投资回收期 可缩短至3年以内。 模块化设计:支持 300kW 至20MW 定制模块,适配不同规模的应用需求。

Application case: In a certain industrial project, this unit achieved an annual power generation of 20.56 million kWh by recycling 115°C hot water, demonstrating significant energy-saving and emission-reduction effects.